In every ambitious construction project, loadbearing is the backbone. Whether you’re erecting a tower floor by floor or maintaining a bridge that carries millions of vehicles each year — knowing how loads are distributed, carried, and changing over time is vital for safety, cost efficiency, and asset longevity.

Yet for too long, engineers have relied on theoretical models and periodic inspections — making critical decisions with partial or outdated data.

It’s time to shift from static checks to continuous certainty.

Railway bridge collapse in Dresden, Germany. September 2024

🏗️ Temporary Loadbearing: Safer, Faster, Leaner

Every construction site has temporary support structures: formwork, back-props, struts, and scaffolds. They’re designed to carry fresh concrete and construction loads — but overloads, underutilized supports, or undetected failures can cause costly delays, damage, or even collapse.

Structural collapse of a reinforced concrete floor structure due to temporary support overloading

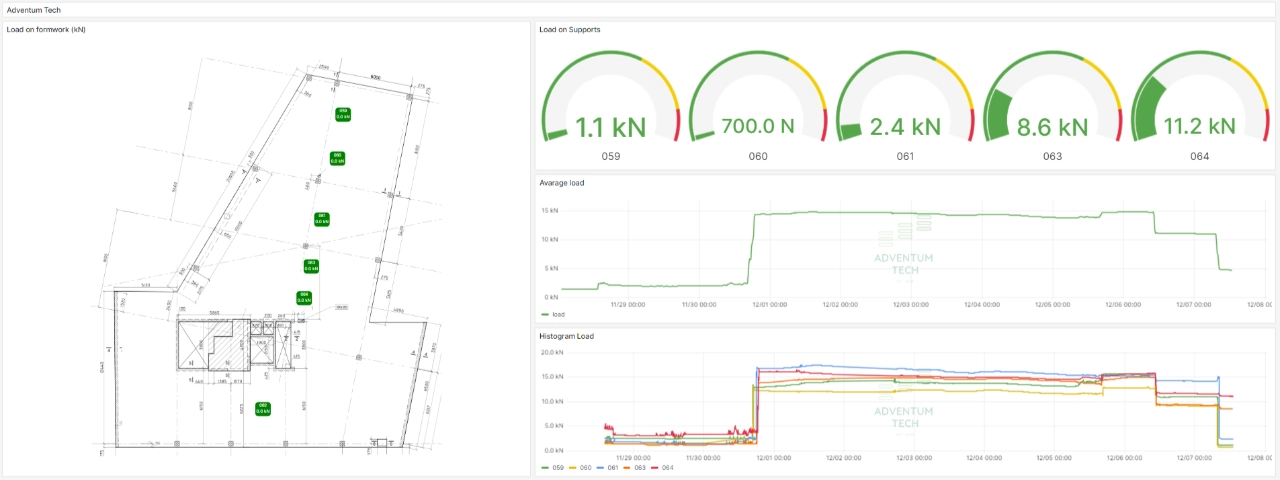

With LiveLoad by Adventum Tech:

✅ Monitor load distribution on props, struts, and temporary beams in real time.

✅ Get instant alerts for overload or load shifts.

✅ Optimize crane operations and propping cycles — removing supports sooner and freeing equipment faster.

LiveLoad sensor network in skyrise project

No more hidden weak points. Just efficient, safe, and predictable construction cycles.

🏢 Permanent Loadbearing: Build Confidence that Lasts

Once the concrete cures, the asset’s real loadbearing story begins. But how does that structure really behave under service loads? Heavy traffic, unexpected settlements, or temperature cycles can slowly degrade performance — until failure risk escalates.

With SlabControl 5.0:

✅ Monitor structural loadbearing capacity continuously for decades — from the pile to the slab, core, or retaining wall.

✅ Validate design assumptions with real data, optimize future designs, and cut unnecessary material waste — supporting CO₂ reduction targets.

✅ Enable predictive maintenance, extended service life, and full digital twin integration.

SlabControl 5.0 20 year real time structural performance monitoring system installed in the highway bridge

For bridge structural monitoring it is recommended to monitor loadbearing through digital bearing pads. Upgrade conventional bridge bearings with LiveLoad Max sensors and other loadbearing columns to capture live force distribution. Your bridge stays under constant watch — today, tomorrow, and for 50+ years to come.

LiveLoad Max system installed to monitor bridges temporary structure structural loadbearing

🔍 Why It Matters

✅ Switch from structural guessing to structural knowing.

✅ Enhance safety — real-time early warnings catch risks before they become disasters.

✅ Save costs through smarter resource allocation, fewer standstills, and faster project delivery.

✅ Boost asset value — well-monitored structures last longer and cost less to maintain.

💡 Best Practice Tip

Combine LiveLoad for short-term and SlabControl 5.0 for lifetime monitoring in critical structures like bridges, tunnels, slabs, or towers. Connect all your data to Adventum Tech software— your hub for visualizing, analyzing, and acting on the real state of your assets.

📢 Coming Next

In The Monitoring Minute — Episode 3, we’ll tackle Existing Railway bridge monitoring — your invisible structural risks, finally visible.

Let’s build smarter, safer, and stronger — together.

For enquiries or any support – contact sales@adventumtech.lv