“A sensor today prevents a shutdown tomorrow. It’s that simple.” Adventum Tech

Real-Time Performance Based Structural Monitoring

Railway bridges are among the most mission-critical infrastructure assets within any national transportation network. As these assets age and loads increase—especially due to the growing volume of cargo traffic—railway authorities face the dual pressure of maintaining absolute safety while optimizing lifecycle costs. Traditionally, inspection intervals have relied heavily on periodic visual assessments, conducted every 2 to 5 years. However, this outdated methodology no longer meets the demands of modern asset management, particularly in an era of rising environmental stressors, heavier freight, and increased operational complexity.

Adventum Tech introduces a new paradigm: performance-based monitoring powered by real-time sensor systems. Through its integrated Digital Bridge solution, Adventum Tech enables continuous structural health data acquisition, empowering railway authorities, asset owners, and engineering consultants to make timely, informed, and cost-effective decisions.

Why Real-Time Monitoring of Railway Bridges is Essential

- Structural Risk Management Rail bridges experience constant dynamic loading from trains, which may lead to progressive structural fatigue. Real-time data enables early detection of micro-deflections, tilting, settlement, or overstressing—preventing catastrophic failures and allowing for timely reinforcement or maintenance.

- Climate Resilience With increased temperature fluctuations, flooding, and extreme weather events, the structural response of railway bridges becomes more volatile. Monitoring tools like TempSense capture real-time thermal data and support proactive decision-making against climate-induced stress

- Freight Overloading Control Cargo companies may unintentionally or deliberately overload trains. When combined with increasing bridge ages, overloading can accelerate structural degradation. Load-bearing monitoring via LiveLoad and SlabControl 5.0 provides clear evidence of overstressing, facilitating contractual enforcement or legal recourse.

- Disaster Response Whether due to seismic activity, derailments, or fire, real-time vibration and deformation tracking systems such as QuakeControl and GroundControl offer critical insights within minutes. This can guide emergency response, assess structural stability post-event, and ensure public safety.

- Enhanced Predictive Maintenance Real-time monitoring allows data-driven maintenance scheduling, reducing unplanned downtime and extending the service life of bridges. Authorities can allocate resources based on actual performance, not estimations or visual guesswork.

- Intelligent Budget Allocation Sensor-based monitoring helps prioritize maintenance by quantifying degradation. Instead of relying on generic inspections, authorities can focus efforts on structures demonstrating active distress, optimizing budget use and resource planning.

- Regulatory and Insurance Benefits Implementing continuous monitoring increases transparency, often resulting in improved risk assessments and reduced insurance premiums. Data logs serve as verifiable records of safety performance and compliance with design expectations.

“Train loads are growing. Climate extremes are rising. Real-time structural awareness is no longer optional.”

Let’s have a look on some of the accidents that could have been prevented if proper structural real-time monitoring systems were applied

When the structural behavior of vital transport infrastructure is not continuously monitored and understood, the cost is often devastating—both in financial and human terms. In an era of rapidly intensifying climate activity, aging infrastructure, and increasing freight volumes, relying solely on periodic visual inspections is no longer sufficient. Super assets such as railway bridges demand constant, real-time insight into their performance to identify early warning signs of stress, fatigue, or environmental impact. Failing to act with foresight exposes entire regions to catastrophic risks—risks that are not theoretical, but have materialized again and again in recent years.

“Monitoring isn’t expensive. Collapse is.”

Dresden, Germany. September 2024

Dresden, Germany – September 2024An aging concrete railway bridge in Dresden experienced partial failure during regular service hours, resulting in halted traffic and significant delays. Although no casualties occurred, the event underscored deficiencies in routine monitoring and the increasing vulnerability of older European infrastructure under evolving weather extremes and loading patterns.

Colorado, bridge collapse near Pueblo, October 16th 2023

Pueblo, Colorado – October 16, 2023A BNSF train derailment occurred when a bridge near Pueblo collapsed beneath a heavy freight load, killing the driver and releasing coal cargo over the tracks. Initial investigations revealed potential issues with the bridge’s load-bearing capacity and age. The collapse highlighted the urgent need for real-time structural diagnostics, especially on high-load freight corridors.

16th of August 2023, Randklev railway bridge

Randklev Railway Bridge, Norway – August 16, 2023The iconic Randklev railway bridge, spanning Norway’s Lågen River, collapsed after intense flooding caused river levels to surge beyond historic limits. Despite modern design, the bridge could not withstand the hydrostatic forces, and a major section gave way. The incident halted railway traffic and emphasized the growing impact of climate change on structural stability in flood-prone regions

24th of June 2023 Montana bridge collapses causing train carrying toxic materials to fall into the Yellowstone river

Randklev Railway Bridge, Norway – August 16, 2023The iconic Randklev railway bridge, spanning Norway’s Lågen River, collapsed after intense flooding caused river levels to surge beyond historic limits. Despite modern design, the bridge could not withstand the hydrostatic forces, and a major section gave way. The incident halted railway traffic and emphasized the growing impact of climate change on structural stability in flood-prone regions

What unites these tragic incidents is a lack of real-time understanding of how these bridges were performing under pressure—whether from water, freight, vibrations, or aging materials. These structures likely exhibited subtle warning signs: increased deflection, micro-vibrations, unusual tilt, or accelerated fatigue. However, without real-time structural performance monitoring, such signals remain invisible until it’s too late. Had sensors like SlabControl 5.0, GroundControl, or QuakeControl been installed, authorities could have received early alerts—enough to temporarily suspend traffic, initiate inspections, and potentially prevent collapse. These cases are a stark reminder that modern infrastructure management must shift from reactive inspection to proactive performance-based monitoring. The technology exists. The stakes demand it.

The Adventum Tech Real-Time Monitoring Suite

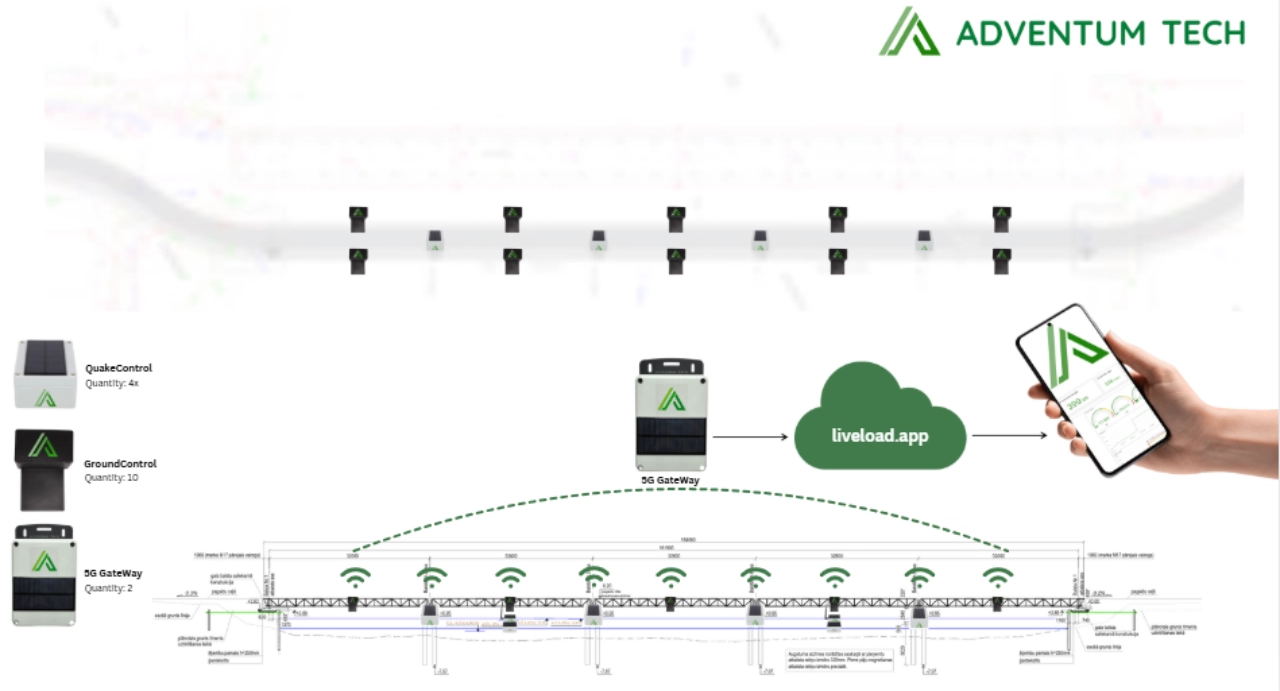

Adventum Tech’s Digital Bridge is a comprehensive solution engineered specifically for rail infrastructure. It integrates multiple sensors installed at structurally significant locations to gather and transmit critical data in real time via Adventum Tech analytical software.

Example solution of Digital Bridge system

“Digital Bridge” dream team:

- LiveLoad Installed on bridge bearings and suspension systems to measure direct load-bearing stresses. Enables accurate assessment of train-induced forces in real time.

- GroundControl A high-resolution triaxial tilt sensor mounted on the top plane of the bridge structure. Detects lateral or vertical displacement, inclination, and vibrations during train passage or environmental loading.

- QuakeControl Vibration sensors deployed on piers and structural foundations. These provide detailed data on oscillations, natural frequency changes, and dynamic load responses.

- SlabControl 5.0 Embedded into the bridge deck, this sensor measures strain, deflection, and distributed loads. Crucial for identifying overdesigned or underperforming elements, contributing to future design optimization and CO₂ reduction.

- StrainControl

Digital Bridge non-loadbearing sensors: GroundControl, QuakeControl, StrainControl

“Railways move economies. Sensors protect that motion.”

From Construction to Operation: Benefits Across the Lifecycle

From the moment a bridge is conceived on paper to the day it bears the weight of trains crossing over it for decades, every stage of its existence carries a responsibility—a responsibility to perform safely, efficiently, and sustainably. In this journey from construction to operation, the ability to truly understand how a structure behaves under real-world conditions has become more critical than ever. Traditional methods, while valuable, fall short in capturing the nuances of dynamic performance, particularly for railway infrastructure, where load patterns, environmental exposure, and safety margins intersect in complex ways.

This is where real-time structural monitoring becomes indispensable. By embedding intelligence into the very skeleton of a bridge or track, Adventum Tech provides project stakeholders with the tools to see the unseen, to know in real-time what was once only assumed. During the construction phase, this means verifying that soil compaction is as designed, that structural components behave as expected under trial loads, and that early movements or anomalies are identified before they evolve into serious risks. GroundControl sensors validate foundation stability, SlabControl 5.0 becomes a permanent witness of structural integrity, and QuakeControl offers vibration analytics that benchmark design expectations against on-site reality.

During Construction:

- Soil and foundation validation through GroundControl

- Embedded slab monitoring with SlabControl 5.0 for long-term insights

- Vibration analysis via QuakeControl to benchmark structural performance during trial run

This data doesn’t fade once the ribbon is cut and the bridge goes into service. Quite the opposite—it becomes more valuable. In operation, the sensors become guardians of the asset’s performance. They deliver the insights needed for predictive maintenance, reducing downtime and optimizing intervention timing. The data they collect becomes the backbone of compliance documentation, ensuring transparency with regulators, insurers, and the public. Perhaps most importantly, this information creates a living model of the structure—integrated with SCADA systems, BIM platforms, and digital twins—that evolves as the bridge ages.

During Operation:

- Predictive maintenance and lifecycle extension

- Identification of anomalies and stress hotspots

- Continuous compliance documentation

- Integration with Railway authority SCADA, BIM, and asset management systems for advanced data analytics and Alerting system

Ultimately, this approach redefines the lifecycle of infrastructure. Rather than build and forget, we now build and understand. We monitor, adapt, and optimize in real time. This results in longer asset life, safer usage, reduced operating costs, and smarter planning for future investments. When we can see what the bridge feels, hears, and resists, we empower decision-makers to act on facts, not assumptions. Adventum Tech believes this is the future of infrastructure—and the pathway to creating intelligent, resilient transport networks that stand the test of time and uncertainty.

Case Application: Pilot Projects and Learnings

In pilot implementations across Europe and the Middle East, Adventum Tech has successfully demonstrated how real-time data enables:

- Reduced false alarms and emergency maintenance callout

- Extension of bridge lifecycle by 10–25%

- Decreased overall maintenance costs by up to 30%

- Precise detection of overloads and settlement zones

One such project included the installation of GroundControl, SlabControl 5.0 and QuakeControl on a high-traffic rail bridge in a mountainous region, where vibration and strain were closely monitored during during bridge operation conditions 24/7 in real time. The data validated structural performance and revealed several “blind areas” for rail authority, where necessary in-depth analyses must be further performed in order to provide sustainable operation and longevity of the super asset.

GroundControl sensors equipping critical railway bridge across the river Daugava in Latvia, Riga for Latvian Railway Authority

When monitoring railway bridges, it is essential to consider the complex interaction between structural behavior and the dynamic characteristics of moving trains—including energy transfer, aerodynamic suction, and kinematic loading. The kinetic energy of a passing train induces variable dynamic forces across the bridge span, which are further influenced by speed, axle load, and the frequency of passages.

Structural behavior monitoring on the bridge deck

In particular, high-speed or heavily loaded trains create transient aerodynamic effects, such as negative pressure zones or suction beneath the carriage, which can impact bridge deck components or unsealed joints. These phenomena, in turn, affect sensor readings, especially those mounted externally or on flexible elements like railings. To ensure data integrity, longer-term monitoring periods allow for noise reduction and filtering of non-structural deflections, such as those caused by wind gusts, particulate disturbances, or rail-induced oscillations. Sensor placement is equally critical. GroundControl sensors are optimally positioned at mid-span to detect real-time triaxial inclinations and strain behavior, while QuakeControl sensors are mounted on piers to capture vibration signatures transmitted through the substructure.

Vibration monitoring on the bridge pier near bridge bearings

However, optimal location calibration may require site survey input to refine sensor layouts based on actual geometries and structure-specific load paths. Furthermore, understanding the kinematic envelope—the maximum dynamic clearance required by various rolling stock—is necessary not only for ensuring safe installation clearances but also for correctly interpreting sensor anomalies during train crossings. By integrating real-time train timing data (either via operator IT systems or passive detection), we can correlate sensor responses with specific rolling stock events, enabling precise cause-effect analysis. Adventum Tech recommends joint development of the monitoring protocol to include these factors and tailor the system architecture to the specific structural and operational characteristics of the monitored railway asset.

Software Integration

Data from all sensors is delivered to Adventum Tech’s secure cloud-based platform that provides:

- Real-time visualization and data dashboards

- Exportable reports for compliance and engineering reviews

- Threshold alerting (based on client-defined limits or FEM modeling)

- Integration APIs with existing IT systems or railway databases

Threshold Planning and Engineering Synergies

Adventum Tech works closely with project stakeholders to align sensor placement and calibration with structural models (FEM). In cases where thresholds are not provided, Adventum Tech assists in determining data interpretation parameters through operational benchmarking and historical analysis.

“Bridges don’t fail overnight. But oversight failure starts the clock.”re, you know.

Final Thought

“Bridges don’t fail overnight. But oversight failure starts the clock.”

Bridges should no longer be inspected based solely on time intervals—but on how they actually perform. The shift from periodic visual assessments to performance-based real-time monitoring represents not just a technological evolution—but a paradigm change in infrastructure management.

“Visual inspections give you snapshots. Sensors give you the full movie.”

Adventum Tech stands ready to partner with forward-thinking railway authorities, consultants, and asset owners to drive this transformation. Our technologies are already in use—proving their value, performance, and impact on safety, sustainability, and profitability.

📢 Coming Next

In The Monitoring Minute — Episode 4, we’ll tackle Groundwater lowering — your invisible structural risks, finally visible.

Let’s build smarter, safer, and stronger — together.