“Unlocking the Power of Concrete Maturity Monitoring”

In modern construction, the speed and safety of your concrete works can make or break your project timeline — yet, far too often, decisions about formwork removal, load application, or structural readiness are based on outdated guesswork or periodic lab samples.

Concrete maturity monitoring changes the game. By tracking the in-situ temperature and time relationship (as defined by ASTM C1074), engineers gain precise real-time insights into strength development. No more waiting “just in case” — or risking premature formwork removal.

📈 Why Concrete Maturity Monitoring Matters

Monitoring concrete curing temperature is essential for ensuring structural integrity, preventing defects, and achieving design specifications. Concrete development is highly dependent on environmental conditions, which can affect strength, durability, and long-term performance.

❄️Cold Weather (Winter & Frost): Low temperatures can slow down the hydration process, delaying strength gain and potentially causing freezing of the fresh concrete, leading to structural weakness or cracking.

☀️ Hot Weather (Summer & Heat): Excessive heat accelerates evaporation and the curing process, increasing the risk of cracking, shrinkage, and non-uniform strength development.

Concrete maturity monitoring changes the game. By tracking the in-situ temperature and time relationship (as defined by ASTM C1074), engineers gain precise real-time insights into strength development. No more waiting “just in case” — or risking premature formwork removal.

💦Evaporation Risks: Improper temperature and humidity control can lead to moisture loss, causing surface cracks and reducing the overall lifespan of the structure.

🌎Environmental Adaptability: TempSense provides proof that concrete was cured under adequate conditions, mitigating crack or deformation risks by accounting for surrounding environmental factors and project location.

What are the direct benefits to monitor concrete maturity?

✅ Faster Formwork Cycles: Remove formwork confidently, days earlier — saving crane time, labor, and cost.

✅ Higher Quality: Detect curing anomalies early, prevent cracks and shrinkage, and protect structural integrity.

✅ Risk Reduction: Shift from guesswork to data-driven decisions, backed by real-time data at every pour.

Concrete maturity monitoring changes the game. By tracking the in-situ temperature and time relationship (as defined by ASTM C1074), engineers gain precise real-time insights into strength development. No more waiting “just in case” — or risking premature formwork removal.

✅ CO₂ Footprint Reduction: Optimized mix designs and leaner construction mean less cement waste and more sustainable concrete use.

🔍 TempSense: The Smart Way to Monitor

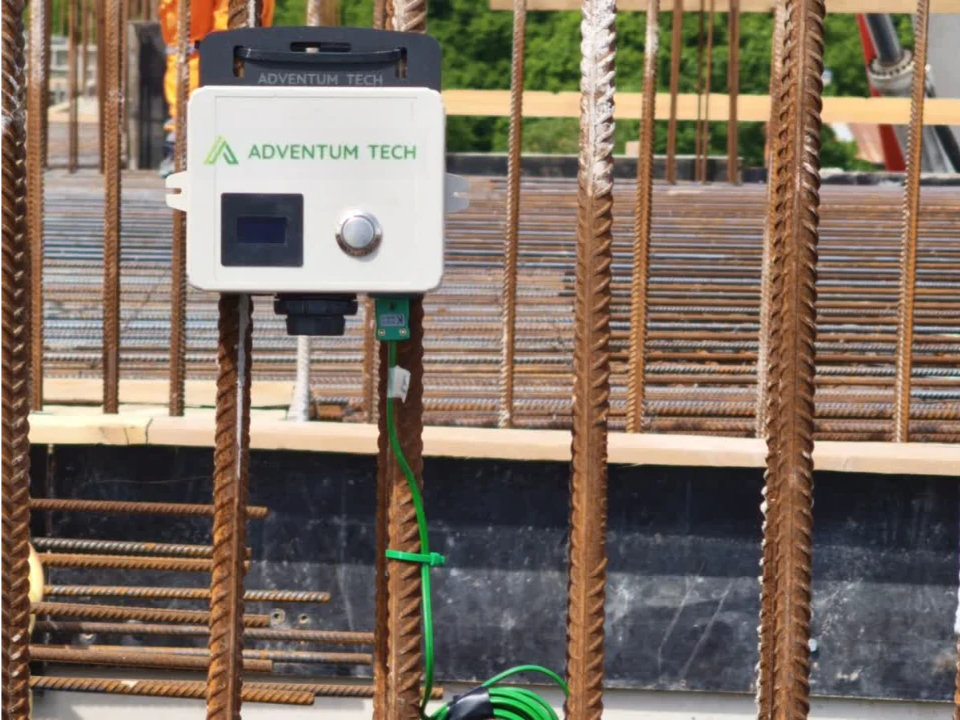

At Adventum Tech, we believe real-time concrete maturity monitoring should be easy, precise, and robust — whether you’re building a bridge deck in the Baltics or a high-rise tower in New York. TempSense is a wireless concrete development monitoring system designed by Adventum Tech to measure the temperature, humidity, and maturity of freshly cast in-situ concrete. Utilizing real-time data and advanced analytics based on the ASTM 1074 standard, TempSense enables construction stakeholders to ensure high-quality, safe, and efficient concrete curing processes across any environmental conditions.

Key Features

🟢Wireless Real-Time Monitoring: Immediate access to curing data for on-site and remote decision-making.

🟢Temperature & Humidity Data: Simultaneously monitors air temperature, concrete curing temperature, and age.

🟢Maturity and Strength Analytics: Automatic ASTM C1074-based calculations to predict concrete maturity.

🟢Secure Data Management: All data is stored and analyzed through the online software, accessible via a secure user interface.

💡 TempSense Pro: Wireless

– Fully wireless, battery-powered sensor.

– Installs directly onto the rebar — embedded with the concrete.

– Sends real-time temperature and maturity data toAdventum Tech software ensuring you know exactly when your concrete hits target strength.

– Ideal for standard pours, slabs, beams, and elements up to 300 mm thickness.

💡 TempSense 3+: Up to 6 monitoring points

– Wireless, battery and PV powered 5G sensor, with connected thermocouples.

– Advanced multi-point system for large or thick structures (piles, cores, massive footings).

– Monitors up to 6 temperature points in parallel with a single sensor unit — offering a complete temperature profile, vertical gradients, and early detection of thermal cracks.

– Concrete structure thickness: unlimited. Designed for deep or complex placements.

How TempSense Enhances Construction Quality

✔️Early Detection of Issues: Prevents cracking, deformations, and structural failures by optimizing curing processes.

✔️Project Efficiency: Facilitates precise decision-making for formwork removal, load application, and timelines.

✔️Compliance Assurance: Ensures adherence to safety and quality standards, reducing risks of rework and delays.

✔️Data-Driven Insights: TempSense-generated data helps improve future project designs, enhancing sustainability and material efficiency.

🏗️ Best Practice Tip

Always plan your sensor placement before the pour. Use TempSense Pro for rapid slab cycles, and TempSense 3+ for deep foundations or massive elements. Connect it all to Adventum Tech software for secure storage, instant alerts, and beautiful compliance reports.

When you measure, you know. When you know, you build better. Start your next concrete pour with data that works as hard as your team does.

📢 Stay Tuned

Next week on The Monitoring Minute — we’ll explore real-time loadbearing monitoring and how to switch from structural guesswork to real structural confidence.

Let’s build smarter, together.

For enquiries or any support – contact sales@adventumtech.lv